High efficiency water dehydrocarbon (oil) coalescer

当水中含有的有机物或油含量不超过3%时(30000mg/L),排水要求油含量小于30mg/L时,采用我们的聚结器是最经济的工艺选择。

When the organic matter or oil content in the water is not more than 3% (30000mg/l),and the oil content required for drainage is less than 30mg/l, it’s the most economical process choice to use our coalescer.

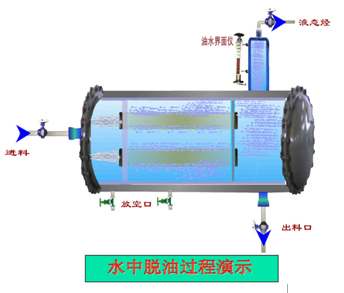

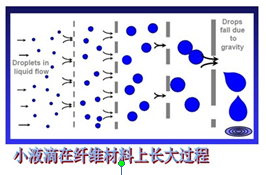

工艺过程:水和水中的分散相碳氢化合物(油)由内向外流经功能滤芯,当通过滤芯的超细纤维厚度层时,分散相中的微小液滴在这里发生碰撞--凝聚--长大过程,长大后的大液滴通过滤芯外的保护层,大油滴依靠比重差在设备的分离区与水进行分离。

Technological process: When water and dispersed phase hydrocarbons (oil) in water flow through the functional filter element from the inside to the outside and pass through the microfiber thickness layer of the filter element, the small droplets in the dispersed phase collide -- agglomerate -- grow here. After growing, the large droplets pass through the protective layer outside the filter element, and the large droplets are separated from water in the separation area of the equipment by means of specific gravity difference.

由于水中杂质颗粒易造成水中脱烃滤芯的堵塞而影响使用寿命,建议在分离器之前设置过滤器,过滤精度最好为5~10微米。

Because the impurities in the water are easy to block the hydrocarbon removal filter element in the water and affect its service life, we recommend that you should set a filter with the best filtering accuracy of 5 ~ 10 microns in front of the separator.

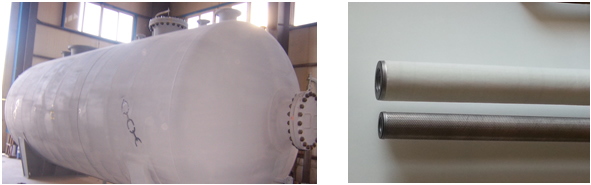

水中脱烃(油)聚结器可适用于石油炼化、煤制油、精细化工、制药工艺过程中有机物和油的回收及含油污水处理(回收废油、排水含油小于15mg/L)。该设备无加药、曝气等能源消耗。

The water dehydrocarbon (oil) coalescer can be applied to the recovery of organic matter and oil and the treatment of oily sewage in the process of petroleum refining, coal to oil, fine chemical industry and pharmaceutical technology (the recovered waste oil and drainage oil are less than 15mg / L). The equipment has no energy consumption such as dosing and aeration

典型应用

分离水中的烃(油)类;去除氨水中的油;

急冷水、冷凝水中除油。

Typical applications:

Separating hydrocarbons (oils) from water; Remove the oil in ammonia water; Remove oil from quench water and condensate.