您现在的位置:首页 > 技术与产品

气体脱液聚结器

Gas dehydration coalescer

在气相的生产、输送、处理和使用过程中,它总是不可避免地受到烃、水等的液滴和固体颗粒的影响,冷凝和雾化过程通常形成稳定的、很微小液雾。气体中的这些杂质能引起许多问题。如:气动元件受损,非正常停车,降低质量,减少产品产量以及增加维修费用、后续反应催化剂失效、副反应增加、压缩机冷凝器冰塞等。

In the process of production, transportation, treatment and use of gas phase, it is always inevitably affected by droplets and solid particles of hydrocarbon, water, etc., and stable and tiny liquid mist is usually formed in the process of condensation and atomization. These impurities in the gas can cause many problems, for example, the pneumatic components are damaged, the abnormal shutdown, the quality is reduced, the product output is reduced and the maintenance cost is increased, the catalyst in the subsequent reaction is invalid, the side reaction is increased, and the compressor condenser is frozen.

所谓气液聚结器,就是通过凝聚材料将微小的液雾捕捉,小液滴在凝聚材料上长大成大液滴,然后通过重力与气相分离。一般设置预过滤器,以去除流体中的杂质颗粒,防止影响凝聚过程。特点如下:

The gas-liquid coalescer is to capture the tiny liquid mist through the condensing material, and the small droplets grow into large droplets on the condensing material, and then separate from the gas phase by gravity. Generally, a pre filter is set to remove impurity particles in the fluid and prevent affecting the coagulation process. The characteristics are as follows:

1、三种拦截机理共同作用来捕捉雾滴

1.Three interception mechanisms work together to capture droplets

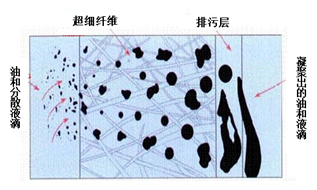

对烃、水和其它液体的雾滴,被凝聚器内部的超细维捕捉(根据具体情况选用不同临界表面张力的凝聚材料),这些微米级纤维对气流形成了曲折的通道,迫使固体颗粒和液体雾滴在惯性碰撞、扩散拦截和直接拦截三个机理的作用下,碰撞到超细纤维上。

The droplets of hydrocarbons, water and other liquids are captured by the ultra-fine dimension inside the condensator (condensing materials with different critical surface tensions are selected according to the specific situation). These micron fibers form a zigzag channel for the air flow, forcing solid particles and liquid droplets to collide with the ultra-fine fibers under the action of three mechanisms: inertial collision, diffusion interception and direct interception.

惯性碰撞是指在流体运动方向变化后,颗粒由于惯性作用而碰撞到纤维上。对于2µm和更大的颗粒,由于它们较大的质量和惯性而保持其原来的运动轨迹,从而撞击到纤维上。

Inertial collision refers to the collision of particles with fibers due to inertia after the direction of fluid movement changes. For particles of 2 µ m and larger, their original motion trajectory is maintained due to their large mass and inertia, thus impacting the fiber.

扩散拦截在气体中对0.2um以下的颗粒是主要的拦截方式。由于布朗运动,颗粒从气流中扩散到纤维表面,在静电作用下吸附到纤维上。

Diffusion interception is the main interception method for particles below 0.2um in gas. Due to Brownian motion, particles diffuse from the air flow to the surface of the fiber and are adsorbed on the fiber under the action of static electricity.

对从0.2um到2um的颗粒来说,只有依靠直接拦截才起作用。直接拦截是指当颗粒直径大于纤维通道时不能通过而被拦截。直接拦截作用是表示孔径分布的最基本的一个特征,孔径越小,直接拦截的效率越高,去除颗粒的效率越高。

For particles from 0.2um to 2um, only direct interception can work. Direct interception means that when the particle diameter is larger than the fiber channel, it cannot pass through and is intercepted. Direct interception is the most basic feature of pore size distribution. The smaller the pore size, the higher the efficiency of direct interception and particle removal.

2、凝聚材料对分散相有良好的浸润性能:对凝聚器来说,仅有细小的孔径是不够的,液体与固体颗粒不同,其形状是可变的,雾滴只有吸附铺展在纤维上,才有利于发生凝聚等过程,使得气相中的液滴实现长大、沉降过程。

2.The agglomerating material has good wettability to the dispersed phase: for the agglomerator, it is not enough to have only a small pore size. And liquid is different from solid particles, and its shape is variable. Only when the droplets are adsorbed and spread on the fiber, it is conducive to the process of condensation, which makes the droplets in the gas phase grow and settle.

3、不破碎(Non-wicking)排放层:在凝聚介质的最外层,紧接着一层不破碎排放层,它使分散相从气流中分离出来,通过重力排放到凝聚器底部,防止已凝聚的液滴破碎,被气体重新带入气流。

3. Non wicking discharge layer: in the outermost layer of the condensing medium, followed by a non-wicking discharge layer, it separates the dispersed phase from the gas flow and discharges it to the bottom of the condenser by gravity to prevent the condensed droplets from breaking and being brought back into the gas flow by the gas.